Closed Loop Fuel System

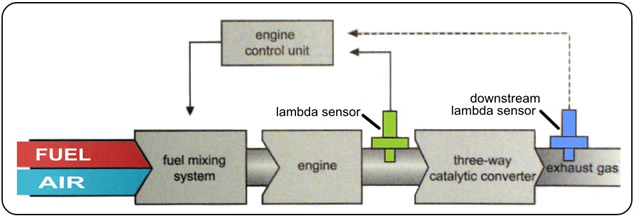

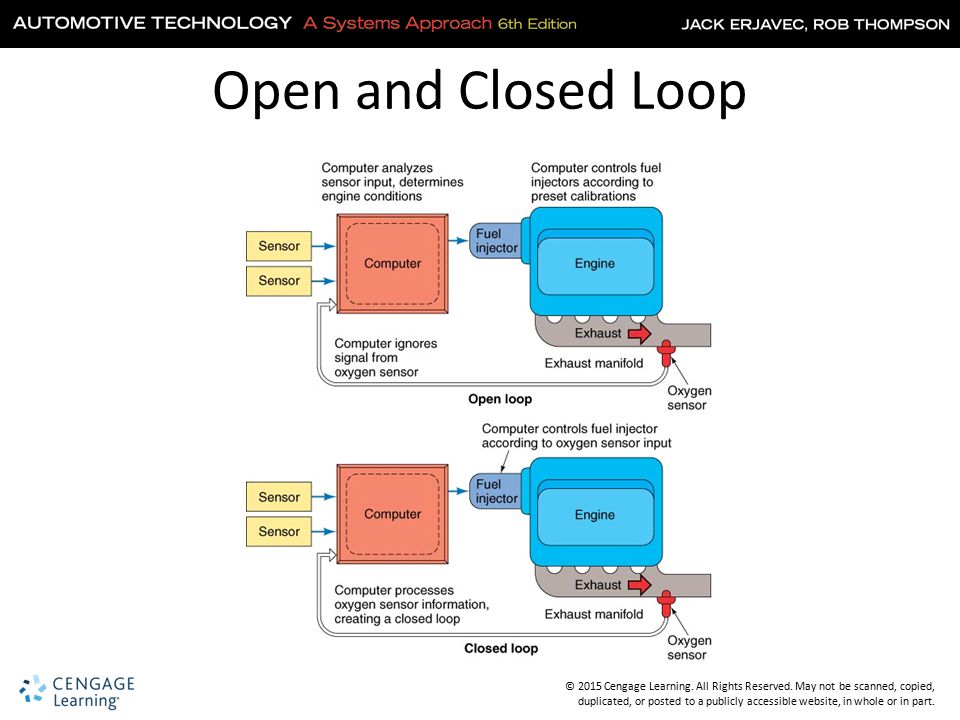

Closed loop fuel system. 1 Openloop 2 Open loop STFT or 3 Closed Loop. This sensor records the. The engine runs in open loop when first started before the oxygen sensors come up to operating temperature.

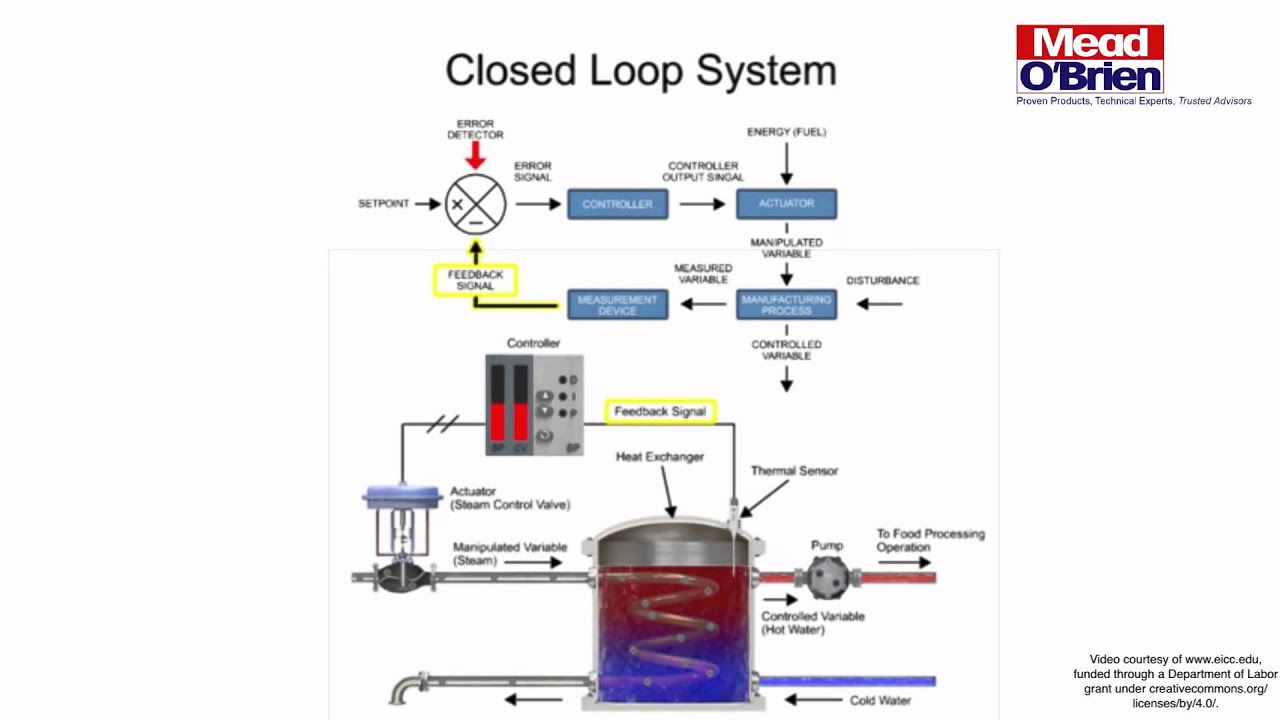

A top-down analysis bottom-up design method 31 was used to design the closed-loop control system for the conceptual oxy-fuel plant. Once the PCM decides that conditions are right it switches to closed loop fuel control which is described below the open loop discussion. In this video I give you a basic description of open loop VS closed loop This may seem very basic however the question has been asked numerous times wha.

The closed loop system uses hydrogen and oxygen gases stored in two gas tanks to run a HTPEM FC stack during the active period. Open and Closed Loop. In this FI system there is an Oxygen sensor or an O2 sensor located inside the exhaust system of the bike.

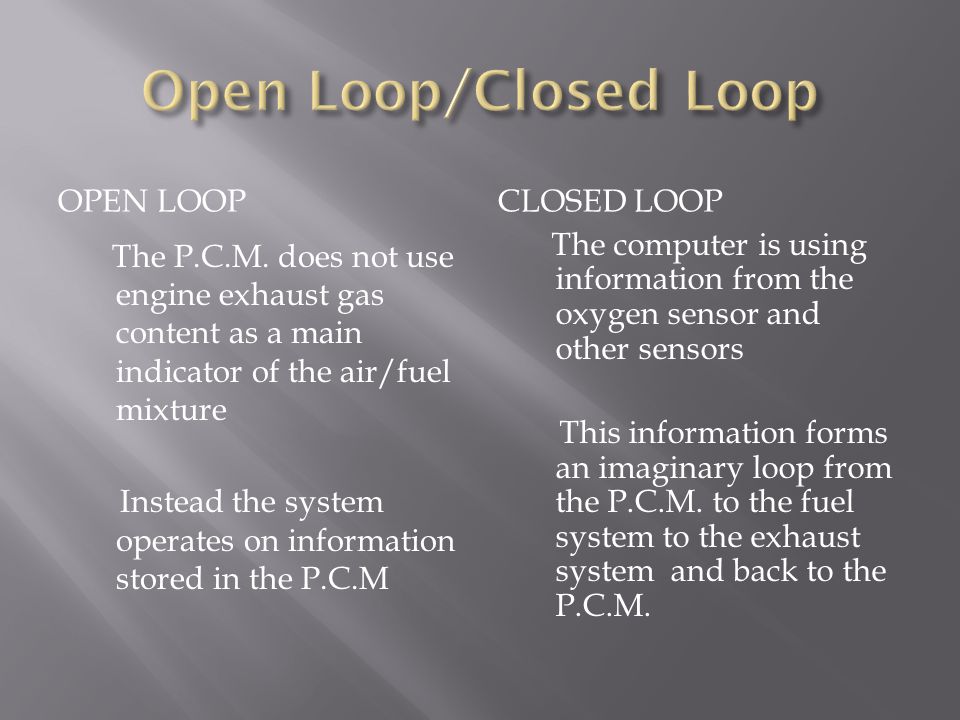

Open loop STFT is usedon some PCMs when the O2 sensors are showing signs of. This is referred to as closed loop operation because the computer is using the O2 sensors input to regulate the fuel mixture. Its called a closed loop system.

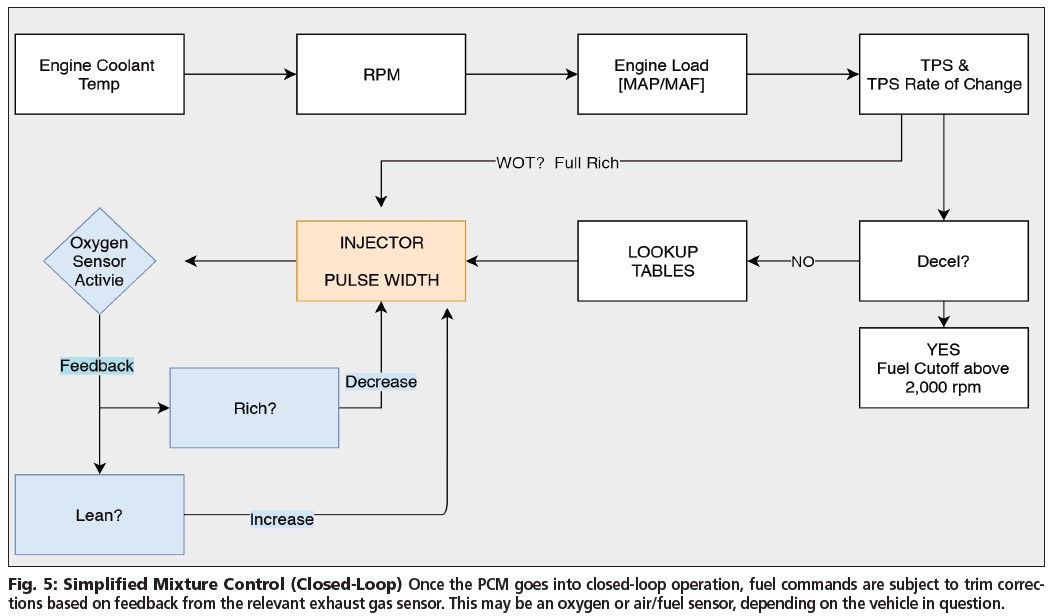

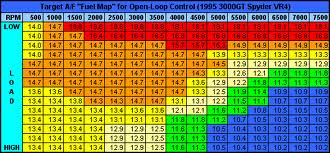

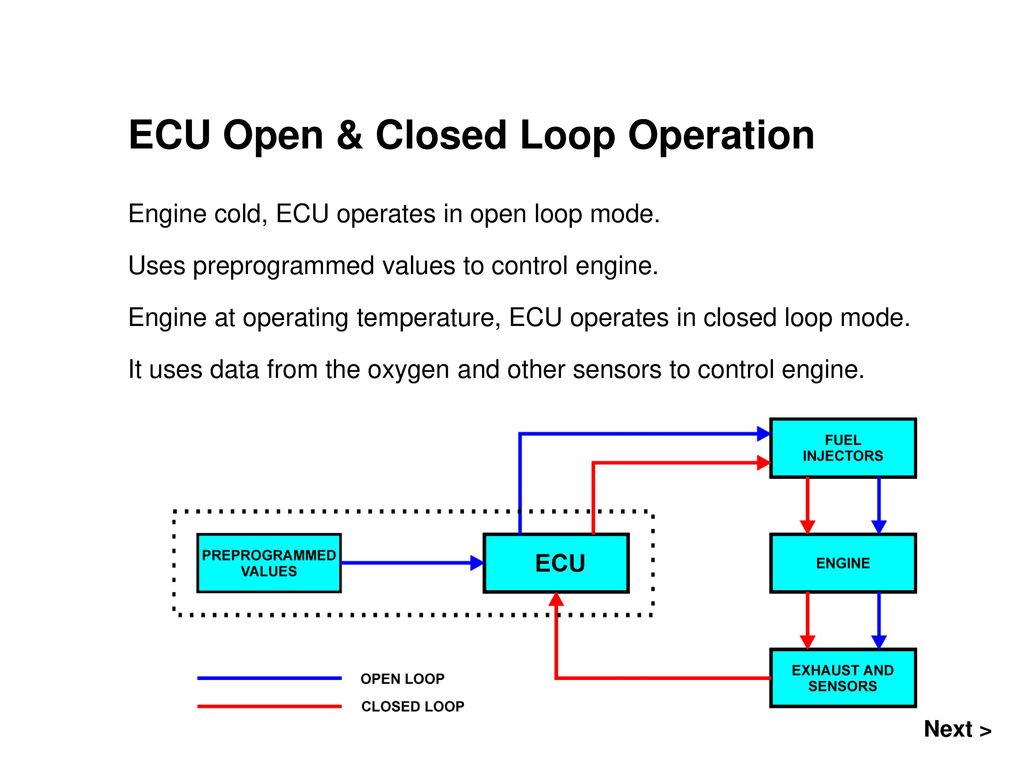

Open loop means the ECU goes outside to look up tables preset amount of air and fuel to calculate how much fuel to give the engine. Open loop is used whenthe O2 sensors are not warmed up failed or when an enrichmentmode such as power enrichment is active. It uses external power to run the electrolyzer and store energy in form of hydrogen and oxygen to run the stack during the next active period.

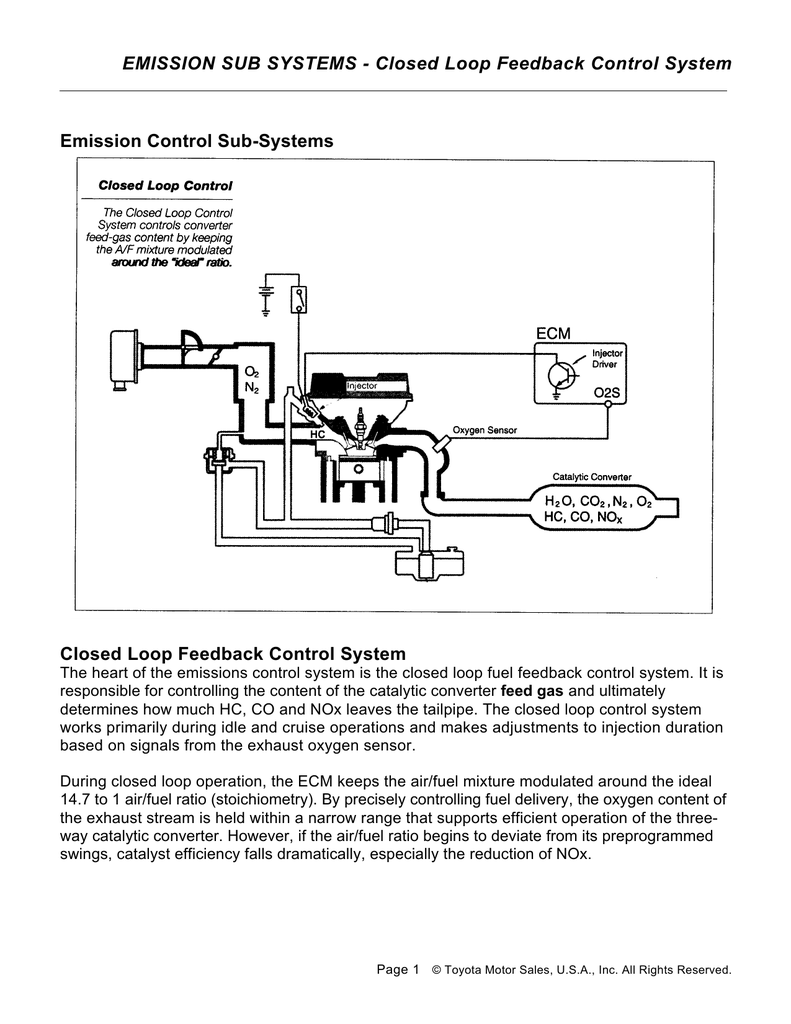

In Closed Loop the ECM will calculate the airfuel ratio injector on-time based on the various sensors but mainly the O2 sensor. This is important in maintaining a perfect AF ratio as there are so many variables affecting the tune of a motor at any given time. The system whose control action is free from the output is known as the open loop control system.

A bottom-up design focuses on designing the regulatory control layer and supervisory control layer. Or the system may be a closed type whereby freshwater treated with an alkaline chemical such as.

1 Openloop 2 Open loop STFT or 3 Closed Loop.

The Powertrain Control Module PCM detects a condition where the vehicle has remained in open loop fuel control from a start-up condition longer than a. In PE mode the scan tool may report that the PCM is in closed loop but it should also report that learning. The Powertrain Control Module PCM detects a condition where the vehicle has remained in open loop fuel control from a start-up condition longer than a. The system whose control action is free from the output is known as the open loop control system. The closed loop system uses hydrogen and oxygen gases stored in two gas tanks to run a HTPEM FC stack during the active period. Open loop is used whenthe O2 sensors are not warmed up failed or when an enrichmentmode such as power enrichment is active. Once the PCM decides that conditions are right it switches to closed loop fuel control which is described below the open loop discussion. Correctly Set Adjustable Fuel Pressure Regulator Hard to Start Car. 03-08-2005 0900 AM 3.

Once warmed up fuel is metered by an active feedback. Top-down analysis aims to define control goals identify controlled and manipulated variables and determine the rate of production. It will be seen that engine AF ignition timing and EGR flow. This sensor records the. Closed loop operation occurs when the oxygen sensors reach their normal operating temp and the coolant temp has reached a predetermined setpoint along with some other things. If you take such a vehicle at high altitude. Closed loop is when the ECU does refer to the o2 sensor for feedback.

Post a Comment for "Closed Loop Fuel System"